What is Geothermal Energy?

Geothermal Energy is a source of renewable energy. Existing hot water is extracted from the earth’s layers. The depth can vary from 500 meters (1,600 ft) to 4,000 meters (13,000 ft) deep. The hot water was created miles deep undergroundand comes up through currents into the outer shell of the earth.

The advantage of this form of renewable energy is that it is not dependent on weather conditions, day or night and seasons. The geothermal heat is used, among other, in greenhouse horticulture, light industries and in the non-rural environment. The temperature of the water varies, at smaller depths up to 1,000 meters the temperature is between the 30 and 40 °C (90-105 °F). Often, a heat pump is needed to increase the temperature. From 2,000 meters (7,500 ft) the extracted geothermal heat has a higher temperature between 70 and 100 °C (160-210°F).

Higher temperatures are required for the heavier industries. This is called Ultra Deep Geothermal Energy (UDG), which is extracted at a depth of more than 4,000 meters (13,500 ft) with a temperature above 130 °C (270 °F).

Production of Geothermal Energy

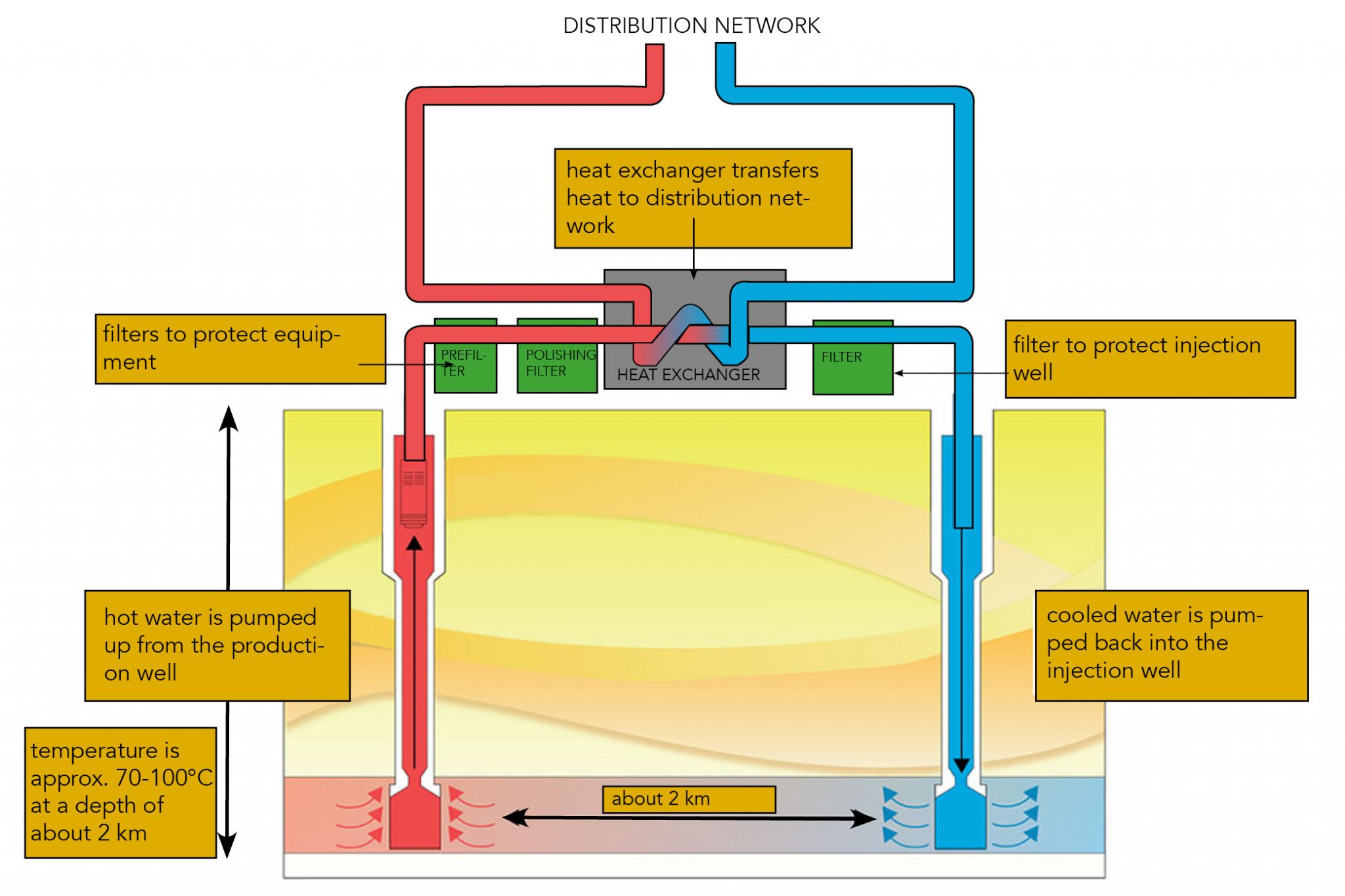

In order to get the geothermal heat out of the ground, earth layers with water (aquifers) are drilled into, this is called an open system. This water is often salt and contains impurities, this water is filtered before it goes towards the heat exchanger. This water is in a closed system and does not come into contact with the water which goes towards the end user. Nevertheless, filtration is an important part because you do not want to fail/damage the heat exchangers and any other equipment. In addition, the cooled water must also be pumped back (injected) into the earth (formation) and must therefore comply with the formation characteristics.

The geothermal installation consists out of two wells, the producer, this is the well where the hot water is pumped out of and the injector, the well where the cooled water is injected into. These wells are about 1 to 2 kilometers (3,250-6,500 ft) apart to prevent the reinjected cooled water from going straight to the producing well.

Geothermal heat is a stable heat source and a constant amount of hot water can be extracted. The lifespan of a well is about 30 years. After use, a well needs a few decades to get back up to temperature again.

The life span and capacity of a well depends on various factors:

- The depth of the well: the deeper the well the warmer the water. The temperature rises approximately 25-30°C per 1 kilometer (72-87 °F/mi).

- The thickness of the earth layer: the thicker the earth layer the more water is available, the minimum thickness of an aquifer is 20-50 meters (65-165 ft)

- The porosity and permeability of the formation: these also determine how much water can be produced and the chance of plugging off the pores in the formation.

Risks of Geothermal Heat Extraction

The production of geothermal energy is not entirely without risks. But if the risks are known in advance, appropriate safety measures can be taken. The risks in producing geothermal heat are:

- Tremors: drilling in the sub-surface can cause tremors and earthquakes. By taking into account existing natural fractures when drilling, the chance of an earthquake can be greatly reduced. After drilling, one must check again whether it is justified on the basis of the pressure in the subsurface or production.

- Escape of gases: There is always a small chance that pressurized gas is found during drilling. The use of valves in the installation withstands any high pressures. The pumped water may also contain gas, which is collected in a gas separator and is returned.

- Natural radiation from production water: In the subsoil there are naturally low-radioactive particles (NORM). These particles can accumulate in the filters and the filter system. If this is the case, the filter waste is discharged separately. The particles can never end up in the heating pipes of homes or businesses because this is a separate water system.

- Contaminants: The steel casing in the wells is designed in such a way that water can never migrate from one layer to another. If the casing should start to leak, this could cause contamination of the groundwater. It is therefore important that a robust design is made and regular (preventive) maintenance is carried out.

- Soil subsidence: In the production of geothermal energy, in principal not much is extracted from the ground, the water is produced, the heat is extracted and the water is re-injected again. The average pressure remains virtually the same and there is therefore little to no subsidence.

The right choice of filters

It is important to properly filter the produced hot water, which greatly improves productivity. Filtration of geothermal water is necessary to minimize the risk of blocking production. A failure in production is usually caused by debris which ends up in moving parts (in drainage, pump parts) or by blockage in the tubes of the heat exchangers.

The most important selection criteria for choosing the right filter are:

- The Flow rate of the hot water to be treated

- Water temperature

- Pressure

- Particle size

- Total amount of suspended solids (and particle size distribution

- Physical/chemical composition of the water

- Injection well properties (porosity, permeability). To prevent plugging of the injection well, one must know the opening diameter of the pores (darcy).

- The absolute filtration rate indicates the maximum size of the particles that can pass through the filter

- The nominal filtration rate indicates the percentage of particles that are likely to pass through the filter.

- The nominal efficiency ratio is the percentage of material blocked by the filter.

- The Beta Ratio is the ratio between the total number of incoming particles and the number of outgoing particles.

The contaminants and solids/particles which are produced with the geothermal liquid are derived from different sources:

- The Reservoir: Rock particles can come along with the flow of water (erosion). If the aquifer is a sandstone formation then a sand screen and filter will have to be in place

- The Well: Due to corrosion, sedimentation and degassing, the well may produce formation particles/solids.

- Downhole Equipment and Installation: During drilling, completion and maintenance work debris may remain behind (for example wear and tear of equipment, coating, remains of cement and/or bridge plugs etc.)

The Degree of Contamination

The contaminants can be divided into different particle sizes

- Fine Solids/Particulates: The liquid is often subjected to a particle size analysis, if it appears that the solids are smaller than 12 μm, then there is no filtration necessary.

- Coarse Solids/Particulates: The coarse particles are often a small piece of rock and/or other deposits that are produced with the geothermal fluid.

- Debris: Debris is often pieces of equipment which have been lost or left behind down-hole during drilling, completion and work-over operations.

Filtration Systems for Geothermal Energy

A filtration system can never be designed too large. The larger a filtration system, the lower the flux over the filter, which increases the lifespan and efficiency of the filtration. However, an oversized filtration system leads to high investment costs.

If too coarse filtration is chosen, there is a risk that the lifespan of the other equipment such as the heat exchanger will become shorter. It is therefore important to make the right choice for a filter. Dutch Filtration has the knowledge, expertise and experience to make the right choice with you.

Most filtration systems in a geothermal system consists out of two or three steps.

Pre-filtration for the removal of coarser particles

This can be done with a hydro-cyclone, an automatic self-cleaning filter or filter bag.

- A Hydrocyclone separates the heavier particles continuously by means of centrifugal force. Clean water flows to the next filtration step. The dirt particles are collected in the flushing chamber, this chamber is automatically emptied.

- A bag filter easily removes dirt particles of 20 microns and coarser. The relatively inexpensive filterbags can be exchanged easily and quickly.The bag filters are used as 2nd step too, after the hydro cyclone and before the cartridge filter to reduce the consumption of relative expensive pleated fine filters.

- A self-cleaning filter has a filter basket with filter mesh where the fine dirt is trapped. The system has a differential pressure switch which initiates the cleaning. The dirt particles are removed by means of a suction scanner automatic without interruption of the filtration flow.

Fine filtration

Fine filtration is usually done by a cartridge filter. Depending on the permeability of the formation, this can be 1 – 10 microns. The water will be filtered with pleated absolute rated filter cartridges of 2.5 inch and 6 inch in diameter and lengths of 40 or 60inch. The special design filters for hot water will be placed into horizontal or vertical filter housings. The closure can be the traditional swing bolts or the new Quick Opening Closure.

The general recommendation is a Duplex or Dual cartridge vessel filtration system so that there is no interruption of the geothermal fluid flow when a filter is cleaned or replaced. The filter vessels/pods can be placed both in series and in parallel, so it is also possible to filter across both filter cartridge vessels. It is also possible to first use a coarse filter cartridges in the first vessel and then let it the fluid pass through finer filter cartridges in the second vessel.

Filtration of Well Test water

Geothermal waste water is also produced when drilling and developing a geothermal well. Well test water is released during the clean-up production of the well and well-testing operations. This water is often salty and usually contains substances so that this water cannot be discharged everywhere. In order to meet the local environmental regulations, most produced/waste water must first be filtered before it can be discharged. Sometimes the water is temporarily stored because people are not sure whether the water meets the legal requirements. This often leads to extra delays and uncertainty. It could happen that a project stagnates because no agreement with local environmental protection agency could be reached whether the water is allowed to be discharged or not. This can create a lot of uncertainty for geothermal projects. It is therefore important that solutions and measures are put in place to minimize the environmental impact and that all local-, municipal-, national-environmental and mining regulations are sufficiently met and adhered to.

Conclusion

Filtration plays an important role in the entire geothermal well process, from drilling, completion and production of the well. A geothermal source can contain many different types of particles, these particles differ in size and composition. It is important that this produced geothermal fluid flow is filtered before it reaches the heat exchangers, in order to prevent clogging of the heat exchangers and the tank and contamination of the re-injection well. The choice of a filter is highly dependent on the composition of the source, especially with sandy geothermal reservoirs many particles come with it. The risks associated with drilling for geothermal energy are comparable with those in the oil and gas sector. With years of experience in the oil and gas industry and the knowledge of the current Geothermal Energy sector, Dutch Filtration can help you make the right choice for a filter installation. We can also advise to optimize a current system; reducing operational costs (such as filter elements) or improving the filtration efficiency with for example installation of a hydrocyclone.

For more information about filtration for the Geothermal Energy industry, please contact us.